ePO 360º laser scanning is one of the most used technologies nowadays when we refer to reverse engineering, as built and retrofit.

With this technology it is possible to virtualize the entire environment to identify interference between equipment and pipes, study the best

positions for installing new equipment in the layout based on 3D reproduction with real dimensions of the environment.

Sectors that most use this technology:

- Automotive;

- Aeronautics;

- Metallurgical;

- Steelworks;

- Consumer goods;

- Pharmaceutical;

- Food;

- Mining;

- Oil and Gas;

Among others…

Point cloud laser scanning process:

We use the most sophisticated and fastest laser scanning equipment on the market. This process consists of analyzing the location, planning the correct positioning of the scanner at different points in the environment and configuring the device for better scanning.

With the equipment turned on, laser beams are emitted from the device, towards an object or interference, which returns the X,

Y, Z position in space, this process is repeated hundreds and thousands of times until it forms a cloud of points of the scanned environment.

Modeling Process from the Point Cloud:

This Process consists of using the point cloud as a template to generate the 3D model of objects and the environment, preserving their real dimensions. We use our specific modeling tools and software for this task, making it possible to reproduce the environment realistically and effectively.

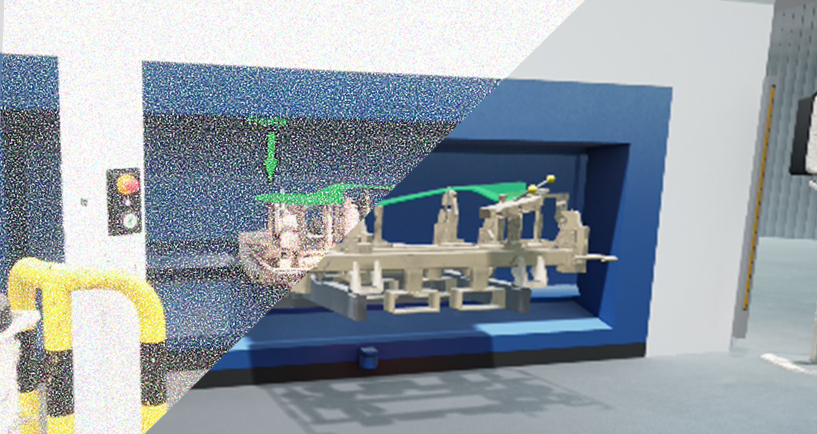

Below are some examples (Point Cloud on the left, 3D Modeling on the right):